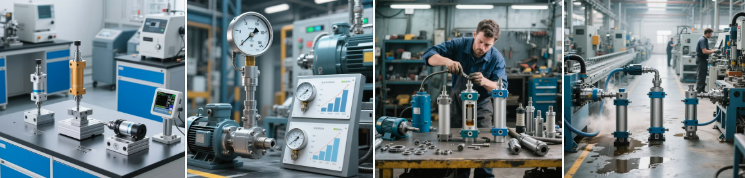

As the industrial landscape continues to evolve, the demand for efficient, precise, and sustainable solutions has led to a significant increase in the adoption of Elektrisk Cylinders. These advanced electromechanical devices offer a range of benefits that make them ideal for various applications across different industries. In this article, we will address the 10 most frequently asked questions about Elektrisk Cylinders, providing comprehensive answers to help you make informed decisions.

1. What is an Elektrisk Cylinder and how does it work?

An Elektrisk Cylinder, also known as an electric cylinder, is an electromechanical device used to produce linear motion. It converts electrical energy into linear movement through a motor driving a spindle or a screw mechanism. When the electric motor is activated, it turns the screw, causing the cylinder rod to move forward or backward. This precise control of linear movement makes Elektrisk Cylinders ideal for applications where accuracy and positioning are crucial.

Basic Components and Operation

Electric Motor: The core component of an Elektrisk Cylinder is the electric motor, which provides the rotational force needed to drive the linear motion. This motor can be a stepper motor, servo motor, or other types depending on the application requirements.

Screw Mechanism: The motor is connected to a screw mechanism, typically a ball screw or a lead screw. The screw converts the rotational motion of the motor into linear motion.

Cylinder Rod: Attached to the screw mechanism, the cylinder rod moves linearly as the screw rotates. The rod can extend and retract, providing the desired linear movement.

Control System: An integrated control system allows precise control over the motor’s speed, direction, and position. This system can be programmable, enabling complex motion profiles and synchronization with other components.

How It Works

Power Activation: When the electric motor receives power, it begins to rotate.

Screw Rotation: The rotation of the motor turns the screw mechanism.

Linear Movement: As the screw rotates, it causes the cylinder rod to move linearly, either extending or retracting.

Precision Control: The control system ensures that the movement is precise and repeatable, meeting the exact requirements of the application.

Applications and Benefits

High Precision: Elektrisk Cylinders offer micron-level repeatability, making them suitable for applications requiring high accuracy, such as precision assembly in electronics manufacturing.

Energy Efficiency: Unlike hydraulic or pneumatic systems, electric cylinders consume power only during actuation, reducing energy consumption and operational costs.

Low Maintenance: With fewer moving parts and no fluids to maintain, Elektrisk Cylinders require less maintenance, reducing downtime and maintenance costs.

Clean Operation: They operate without the risk of fluid leakage, making them ideal for clean environments such as food processing and medical applications.

Programmability: These cylinders can be easily integrated into automation systems and controlled through various electronic interfaces, enabling complex and dynamic motion control.

2. What are the key benefits of using Elektrisk Cylinders?

Elektrisk Cylinders offer several key benefits, including:

High Precision: They provide micron-level repeatability and smooth acceleration/deceleration, making them suitable for applications requiring high accuracy.

Energy Efficiency: Unlike hydraulic or pneumatic systems, electric cylinders consume power only during actuation, reducing energy consumption.

Low Maintenance: With fewer moving parts and no fluids to leak or replace, Elektrisk Cylinders require less maintenance.

Environmental Friendliness: They do not produce harmful waste like hydraulic oil or compressed air, making them a greener alternative.

Programmability: Electric cylinders can be easily integrated into automation systems and controlled through various electronic interfaces.

3. What are the common applications of Elektrisk Cylinders?

Elektrisk Cylinders are versatile and precise actuators that find applications across various industries. Their ability to provide high-precision linear motion makes them suitable for a wide range of tasks. Here are some common applications:

Automotive Manufacturing

Door Fitting: Elektrisk Cylinders are used to precisely position and fit car doors, ensuring a perfect seal and fit.

Engine Component Assembly: High-precision movements are required to assemble engine parts, where Elektrisk Cylinders provide the necessary accuracy.

Robotic Welding: In robotic welding stations, these cylinders control the movement of welding arms, ensuring consistent and precise welds.

Medical Equipment

Surgical Tables: Elektrisk Cylinders enable precise adjustments of surgical tables, allowing surgeons to position patients accurately.

Robotic Surgery Systems: These systems rely on precise motion control to perform minimally invasive surgeries with high accuracy.

Laboratory Automation: In automated lab equipment, Elektrisk Cylinders handle delicate samples and instruments with precision.

Food and Beverage

Packaging Machines: Used in packaging lines to control the movement of packaging materials and products, ensuring consistent packaging.

Conveyor Systems: Elektrisk Cylinders drive conveyor belts, providing smooth and precise control over product movement.

Automated Filling Equipment: These cylinders control the filling process in beverage and food packaging, ensuring accurate and consistent product volumes.

Entertainment Machines

4D Cinema Seats: Elektrisk Cylinders provide the motion effects in 4D cinema seats, enhancing the immersive experience for viewers.

Virtual Reality Platforms: In VR applications, these cylinders create realistic motion simulations, enhancing user engagement.

Mobile Machinery

Electric Forklifts: Elektrisk Cylinders are used in the lifting mechanisms of electric forklifts, providing precise control and energy efficiency.

AGVs (Automated Guided Vehicles): These vehicles use Elektrisk Cylinders for precise movement and positioning in warehouse and manufacturing environments.

Lifting Platforms: In lifting platforms, Elektrisk Cylinders provide smooth and controlled lifting and lowering of loads.

4. How do Elektrisk Cylinders compare to hydraulic and pneumatic cylinders?

The table provides a concise comparison of Elektrisk Cylinders with their pneumatic and hydraulic counterparts, highlighting key differences in precision, energy efficiency, space usage, cleanliness, maintenance, programmability, cost of ownership, and safety. Elektrisk Cylinders stand out for their high precision, energy efficiency, compact design, low maintenance, and enhanced safety features, making them a superior choice for modern industrial applications where sustainability and precision are paramount.

| Feature | Elektrisk Cylinder | Pneumatic Cylinder | Hydraulic Cylinder |

| Precision | High (µm-level, servo control) | Low-Medium (no feedback) | Medium (prone to drift) |

| Energy Efficiency | High (power used only in motion) | Low (compressed air leaks) | Low-Medium (energy for pump) |

| Space Usage | Compact (integrated drive) | Moderate (cylinder + valves) | Bulky (pumps, fluid lines) |

| Cleanliness | Oil-free, closed design | Noisy, potential air leaks | Risk of oil leakage |

| Maintenance | Low (firmware updates) | Moderate (valve seals) | High (fluid, seal, filter) |

| Programmability | Full motion profiles | Limited to on/off | Limited proportioning |

| Cost of Ownership | Moderate upfront, low TCO | Low purchase cost, higher OPEX | Mid initial, high OPEX |

| Safety | High (IP65, feedback) | Moderate | Fire risk due to oils |

5. What are the technical specifications of Elektrisk Cylinders?

Technical specifications for Elektrisk Cylinders can vary widely depending on the model and manufacturer. For instance, the HEZ series from HYDAC is a prime example of the diverse range of options available in the market. These cylinders are designed to meet a wide array of application requirements, making them highly versatile and adaptable to different industrial needs.

Key Specifications of the HEZ Series

The HEZ series offers a broad range of force capabilities, with cylinders capable of exerting forces from 3,000 N to 40,000 N. This wide range ensures that there is a suitable model for applications ranging from light-duty tasks to heavy industrial processes.These cylinders come with various stroke lengths, allowing for precise control over the linear movement. Whether the application requires short, precise strokes or longer movements, the HEZ series can be configured to meet these needs.

The HEZ series can achieve speeds up to 546 inches per minute, making them suitable for applications that require rapid movement and high throughput. This high-speed capability ensures efficient operation in fast-paced industrial environments.Available in different configurations such as coaxial and parallel, these cylinders can be tailored to fit the specific spatial and mechanical requirements of various machines and systems. The flexibility in configuration ensures optimal integration into existing or new setups.

Additional Technical Details

The HEZ series is known for its high precision, with micron-level repeatability and smooth acceleration/deceleration. This level of precision is crucial for applications in industries such as electronics manufacturing, where accuracy is paramount.These electric cylinders are designed to be highly energy-efficient, consuming power only during actuation. This not only reduces operational costs but also aligns with sustainability goals by minimizing energy waste.

With fewer moving parts and no fluids to maintain, the HEZ series requires less maintenance compared to hydraulic or pneumatic systems. This reduces downtime and maintenance costs, enhancing overall operational efficiency.The HEZ series is designed with safety in mind, featuring IP65 ratings and feedback mechanisms that ensure reliable and safe operation. These features are particularly important in environments where worker safety and equipment reliability are critical.

Customization and Flexibility

One of the standout features of the HEZ series is its customization options. Customers can choose from different bore sizes, stroke lengths, and force capabilities to tailor the cylinder to their specific application needs. This level of customization ensures that the cylinder performs optimally in its intended environment, whether it’s a small laboratory setup or a large-scale manufacturing plant.

6. How can Elektrisk Cylinders be customized for specific applications?

Elektrisk Cylinders offer a high degree of customization to meet the unique requirements of various applications. This flexibility ensures that the cylinders can be tailored to fit specific needs, enhancing performance and efficiency. Here are some ways in which Elektrisk Cylinders can be customized:

Customization Options

Elektrisk Cylinders can be configured with different stroke lengths to match the specific movement requirements of your application. Whether you need a short stroke for precision tasks or a longer stroke for broader movements, customization ensures optimal performance.Depending on the application, the force and speed of the cylinder can be adjusted. High-force applications may require more powerful motors and robust screw mechanisms, while high-speed applications may need optimized gearing and motor control systems.

Modular Design and Flexibility

FDR’s modular design philosophy allows for a high degree of customization. Their small-lot production capabilities make it possible to create bespoke solutions tailored to individual customer requirements. This flexibility ensures that each cylinder is optimized for its specific application, providing the best possible performance and reliability.

Customization Process

Define Application Requirements: Clearly outline the specific requirements of your application, including force, stroke length, speed, and environmental conditions.

Consult with Experts: Work with knowledgeable engineers and technicians to discuss your needs and explore customization options.

Select Custom Features: Choose from available customization options, such as stroke length adjustments, specialized mounts, and integrated drives.

Prototype and Test: Request prototypes or samples to test the customized cylinder in your application environment. This step ensures that the final product meets your exact specifications.

Finalize and Implement: Once the customization is validated, finalize the design and implement the customized Elektrisk Cylinder into your system.

7. What are the future trends for Elektrisk Cylinders?

Future trends for Elektrisk Cylinders include:

Electrification of Mobile Machinery: Increasing adoption in electric forklifts, AGVs, and lifting platforms.

Miniaturization and Micro-Motion: Growing demand for tiny cylinders suitable for laboratory automation and micro-robotics.

Smart Sensors for Predictive Use: Integration of temperature, vibration, and torque sensors for predictive maintenance.

Automotive & EV Assembly: Increased use in electric vehicle manufacturing, including charging stations and in-vehicle mechanisms.

Custom/On-Demand Servomotion: Rising demand for customized solutions with odd stroke lengths and specialized mounts.

8. What are the challenges and limitations of Elektrisk Cylinders?

While Elektrisk Cylinders offer numerous benefits, there are some challenges and limitations to consider:

Higher Initial Costs: The upfront cost of electric cylinders can be higher compared to hydraulic or pneumatic systems.

Load Capacity: They typically have a lower load capacity compared to hydraulic systems, making them less suitable for very heavy loads.

Power Supply Requirements: A reliable power supply is necessary, and power outages can cause issues.

Speed Limitations: In some cases, electric cylinders may reach their limits at very high speeds.

9. How can I choose the right Elektrisk Cylinder for my application?

Choosing the right Elektrisk Cylinder involves considering several key factors to ensure optimal performance and compatibility with your specific application. Here’s a detailed guide to help you make an informed decision:

Key Factors to Consider

Required Force

Determine the force required for your application. Elektrisk Cylinders are available in a wide range of force capabilities, from a few hundred Newtons to tens of thousands of Newtons. For example, the HEZ series from HYDAC can exert forces ranging from 3,000 N to 40,000 N.Consider whether the force will be applied dynamically (during motion) or statically (while stationary). Dynamic forces may require higher torque and power ratings.

Stroke Length

Identify the stroke length needed for your application. Elektrisk Cylinders come with various stroke lengths, from a few millimeters to several meters. Ensure the chosen cylinder can accommodate the full range of motion required.Consider the space constraints in both the extended and retracted positions to ensure the cylinder fits within your machine or system.

Speed

Determine the speed at which the cylinder needs to operate. Some applications may require rapid movement, while others may need slower, more controlled motion. The HEZ series, for example, can achieve speeds up to 546 inches per minute.Consider the acceleration and deceleration profiles required. Smooth acceleration and deceleration can reduce wear and improve precision.

Precision

Assess the level of precision required. Applications such as electronics assembly may need micron-level repeatability, while others may tolerate greater tolerances.Consider whether you need integrated feedback systems for real-time monitoring and control. Servo-controlled cylinders offer higher precision and programmability.

10. What is the future potential of Elektrisk Cylinders in the market?

The future potential for Elektrisk Cylinders is promising, driven by trends such as electrification, miniaturization, and the increasing demand for smart, sustainable solutions. As industries continue to adopt Industry 4.0 and smart manufacturing practices, the market for electric cylinders is expected to expand significantly. By staying ahead of these trends and continuously innovating, manufacturers like FDR can solidify their position as leaders in the electric actuation market.

Conclusion

Elektrisk Cylinders offer a range of benefits that make them ideal for various industrial applications. Their high precision, energy efficiency, low maintenance, and programmability set them apart from traditional hydraulic and pneumatic systems. As the market continues to evolve, the adoption of Elektrisk Cylinders is expected to grow, driven by trends such as electrification, miniaturization, and the increasing demand for smart, sustainable solutions. By addressing the most frequently asked questions, we hope to provide valuable insights and help you make informed decisions when considering Elektrisk Cylinders for your applications.To learn more, please visit Suzhou Fengda Automation Equipment Technology Co., Ltd.