Introduction

In the world of motion simulation, precision is key. 3DOF systems are essential for replicating the critical movements of pitch, roll, and yaw. These systems power everything from flight simulators to VR experiences, enabling lifelike immersion.

In this article, we’ll dive into the control principles behind 3DOF systems, explaining their components and how they work. You’ll learn how these systems bring realism to various applications.

At FDR, we provide high-performance motion platforms, ensuring optimal precision and immersion. Learn more about our products to enhance your simulation experience.

Understanding Three Degree of Freedom Systems

What is a Three Degree of Freedom System?

A 3DOF system provides movement in three independent rotational directions, each representing a critical motion required for realistic simulations.

● Pitch: Movement along the horizontal axis, typically up and down, as seen in aircraft flying up or down.

● Roll: Movement along a front-to-back axis, where the platform tilts side to side.

● Yaw: Rotation around a vertical axis, simulating the turning of an object either left or right.

These movements are essential for providing a realistic feel in flight simulators, VR experiences, and robotic movements. By simulating real-world movements, these systems create a highly immersive experience for the user.

Type of Motion | Description | Common Applications |

Pitch | Up-and-down rotation around a horizontal axis. | Aircraft take-off, VR gaming, simulation training |

Roll | Tilting motion around the axis extending from front to back. | Aircraft bank turns, racing simulators |

Yaw | Rotation around a vertical axis, turning left or right. | Aircraft turning, VR experiences, simulators |

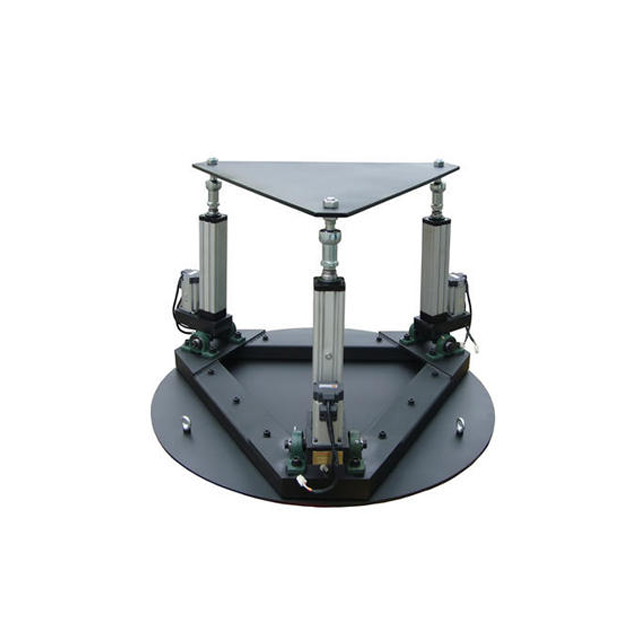

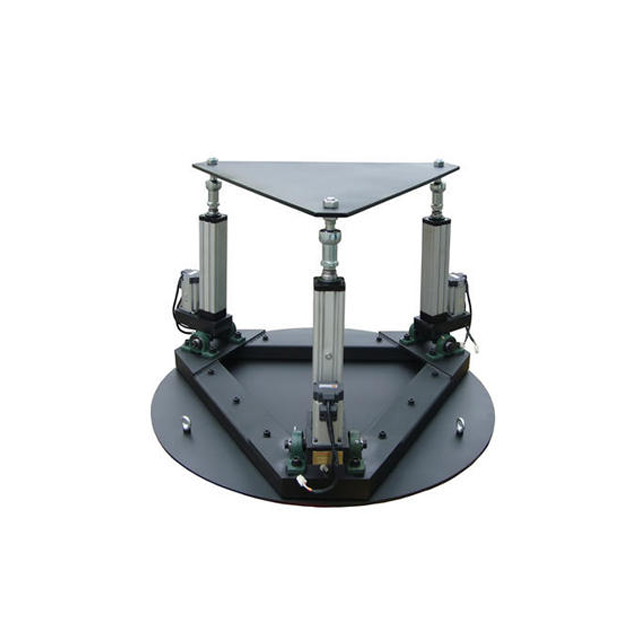

Components of a 3DOF System

The main components responsible for the function and control of 3DOF systems include:

● Actuators: These motor-driven devices control the movement of the platform. Actuators are critical for producing precise pitch, roll, and yaw movements, allowing the platform to replicate the motions needed for realistic simulations. They convert electrical signals into mechanical motion, offering smooth and accurate responses to user input.

● Sensors: Sensors track and monitor the position and movement of the platform. By continuously collecting data on the platform’s orientation and motion, sensors provide the necessary information for adjusting movements in real-time. These sensors are vital for ensuring that the system remains in sync with the user’s input and provides continuous feedback.

● Control Systems: These systems use advanced algorithms to synchronize the actuators and sensors. Control systems process the sensor data and adjust the actuator movements to ensure that the platform responds smoothly and accurately to changes in user input. They ensure that all movements, whether fast or subtle, are executed with high precision, enhancing the realism of the simulation.

Together, these components create a real-time feedback loop that makes the simulation feel responsive and realistic, ensuring an immersive experience for users across various applications such as flight training, VR environments, and robotics.

Control Principles of 3DOF Systems

Feedback Loops in Motion Control

Feedback loops are the backbone of 3DOF systems, allowing them to adjust in real time based on sensor data. These loops ensure that the system remains stable and precise throughout operation. By continuously receiving input from sensors, the control system can adjust the actuators’ movements to create the most accurate motion possible.

In practical applications, these systems are adjusted to suit various speeds and conditions. For example, a flight simulator may require faster, sharper movements in certain scenarios, while in a VR experience, more subtle motions may be sufficient for the user’s immersion.

Control Algorithms and Synchronization

Advanced control algorithms are key to ensuring that the actuators work harmoniously. These algorithms process sensor data and adjust actuator inputs to ensure that movements are not only precise but also smooth. Synchronization is critical, as any lag or discrepancy between actuator movements can disrupt the simulation experience.

For example, in a flight simulation, when the user adjusts their position in the virtual cockpit, the system needs to immediately reflect changes in pitch, roll, and yaw to maintain immersion.

Real-Time Adjustment and Adaptability

An important feature of 3DOF systems is their ability to adapt to user inputs or environmental changes in real-time. This adaptability allows the platform to respond to quick or unexpected movements, ensuring that users always feel connected to their virtual environment. Whether simulating an airplane’s quick maneuver or a car’s sharp turn, the platform’s ability to instantly adjust its position is crucial for maintaining realism.

This adaptability also improves user comfort by preventing unnecessary motion or force, ensuring that the movements are as smooth and natural as possible.

Flight Simulation and Training

Flight simulators rely heavily on 3DOF systems to replicate the sensations of flying. Pilots use these simulators to practice maneuvers, emergency procedures, and familiarize themselves with different flight conditions. By simulating the key movements of pitch, roll, and yaw, these systems help train pilots in a safe and cost-effective manner.

The real-time adjustment of 3DOF systems helps simulate various flight conditions, from turbulence to sharp turns, giving pilots a realistic experience without the risks associated with actual flying.

Robotics and Manufacturing

In robotics, 3DOF systems allow for precise movement control in tasks like assembly, inspection, and material handling. Robotic arms use 3DOF systems to position themselves accurately within a defined space, ensuring that each action is performed with high precision.

The versatility of 3DOF systems also helps in manufacturing settings, where automation systems are used for repetitive tasks that require consistency and high precision.

Virtual Reality (VR)

In VR, 3DOF platforms enhance immersion by providing users with physical feedback in response to their movements. This feedback helps users feel as though they are interacting with the virtual world, improving their overall experience.

For instance, in a racing simulator, a VR user can feel the effects of acceleration, deceleration, and sharp turns, making the experience more realistic. Similarly, 3DOF systems can be used to simulate flying, allowing the user to feel the subtle movements of the aircraft as they adjust their virtual position.

Technological Innovations in 3DOF Systems

Advancements in Actuator Technology

Recent developments in actuator technology have made 3DOF systems more efficient and precise. The integration of high-performance actuators has led to smoother, faster, and more responsive motion. These advances have allowed motion platforms to offer more detailed feedback, which is essential for high-stakes simulations such as military training or aviation.

Moreover, new actuator designs are more compact and energy-efficient, making them suitable for use in both commercial settings and consumer-grade simulations.

Software and Control Systems

The algorithms that control 3DOF systems are constantly improving. Modern software integrates machine learning to adapt to user behavior, predicting and adjusting movements in real time. These systems ensure that users experience motion that is not only accurate but also adaptive to dynamic scenarios.

Enhanced real-time control has improved the overall user experience, making it more fluid and responsive.

Integration of Sensors for Precision

The role of sensors in 3DOF systems has grown significantly with advances in sensor technology. High-resolution sensors provide continuous feedback on the position and velocity of the platform. This real-time data is critical for maintaining the precision of movements, especially during high-speed or high-accuracy simulations.

For example, optical sensors now allow for even more precise tracking, ensuring minimal lag and a smoother experience for users.

Technology | Improvement | Impact on Simulation |

Brushless DC (BLDC) Motors | Enhanced efficiency and quieter operation | Reduces power consumption and improves user comfort |

Real-Time Adjustment Systems | Dynamic adjustment based on user input | Ensures smoother transitions and more accurate feedback |

Advanced Sensor Integration | Precise tracking and adjustment of movements | Provides more lifelike and responsive simulation |

Compact Actuators | Smaller and more efficient actuator designs | Enables integration into smaller spaces without sacrificing performance |

=Challenges in Controlling 3DOF Systems

Achieving Precision with Actuators

While actuators have become more efficient, achieving perfect precision remains a challenge. Even slight variations in actuator movement can cause disruptions in the simulation experience. To maintain smooth and realistic motion, constant monitoring and real-time adjustments are essential. This is particularly crucial in applications like flight simulators, where precise movements of pitch, roll, and yaw are vital for realistic training and immersion. The complexity of maintaining flawless actuator performance requires high-end components and effective calibration techniques.

External Environmental Factors

Factors such as temperature fluctuations or vibrations can significantly impact the performance of 3DOF systems. External conditions may introduce inconsistencies in the simulation's behavior, causing potential inaccuracies. To mitigate these environmental influences, many advanced 3DOF systems are equipped with adaptive technology that can adjust the system's performance in real-time, ensuring stability and maintaining accurate motion even in less-than-ideal conditions. This technology plays a crucial role in sustaining the reliability of motion systems across different operating environments.

Future of 3DOF Systems

Emerging Technologies and Trends

The future of 3DOF systems is incredibly promising, with exciting advancements on the horizon. The integration of artificial intelligence (AI) and machine learning is expected to significantly enhance the performance of these systems. AI will enable 3DOF platforms to predict and adapt to user movements in real time, improving accuracy and immersion. This technology will allow systems to provide even more lifelike simulations by continuously adjusting to dynamic user interactions. With these innovations, the potential for creating hyper-realistic and responsive simulations is limitless, further pushing the boundaries of motion simulation technology.

Expanding Applications

As 3DOF technology continues to evolve, its applications are extending far beyond traditional training and entertainment fields. The versatility of 3DOF systems is opening doors to new industries such as medical simulations, robotic surgery, and advanced research. In medical training, these systems can simulate complex procedures and environments, providing a safe and cost-effective way for practitioners to gain experience. Similarly, in robotic surgery, precise and real-time motion feedback from 3DOF platforms is helping surgeons develop and refine their skills in a virtual setting. The broadening range of applications ensures that 3DOF systems will remain integral to motion simulation for years to come, with continued advancements that support a wide array of industries.

Conclusion

Three Degree of Freedom (3DOF) motion systems are integral to various simulation platforms, including flight training and robotics. By accurately replicating movements in pitch, roll, and yaw, they enhance user experience and improve training environments. As technology progresses, 3DOF systems will offer even more precision and adaptability. FDR provides cutting-edge motion platforms that elevate immersive experiences for both professionals and enthusiasts.

Tip: Regular maintenance and upgrading of the system’s components, such as actuators and sensors, are essential to maintaining optimal performance and extending the life of 3DOF systems.

FAQ

Q: What is a Three Degree of Freedom (3DOF) system?

A: A 3DOF system allows movement in pitch, roll, and yaw, providing realistic motion feedback for simulations in flight training, robotics, and VR experiences.

Q: How do control principles work in 3DOF systems?

A: Control principles in 3DOF systems rely on real-time feedback loops, advanced control algorithms, and synchronization to ensure precise and smooth motion based on user input.

Q: What are the main applications of 3DOF systems?

A: 3DOF systems are widely used in flight simulators, racing simulators, and virtual reality environments, providing immersive and responsive movement.

Q: How do advancements in actuator technology improve 3DOF systems?

A: Recent actuator advancements enhance the efficiency and precision of 3DOF systems, providing smoother motion and greater adaptability in simulations.