Imagine testing a full-scale vehicle or aircraft component with precise motion control. That's where a 6DOF motion platform excels. These platforms simulate real-world conditions, crucial for industrial testing. In this post, you'll learn what a 6DOF motion platform is, its importance in handling heavy payloads, and its diverse industrial applications.

Understanding the 18000 kg Payload Capacity

Engineering Challenges and Solutions

Handling a 18000 kg payload on a 6DOF motion platform presents unique engineering challenges. The platform must maintain precision and stability despite the heavy load. Structural components require robust materials and design to prevent deformation under stress. Actuators and motors must deliver high torque and force while ensuring smooth motion without jerks. Advanced control algorithms compensate for the increased inertia, maintaining accurate positioning across all six axes.

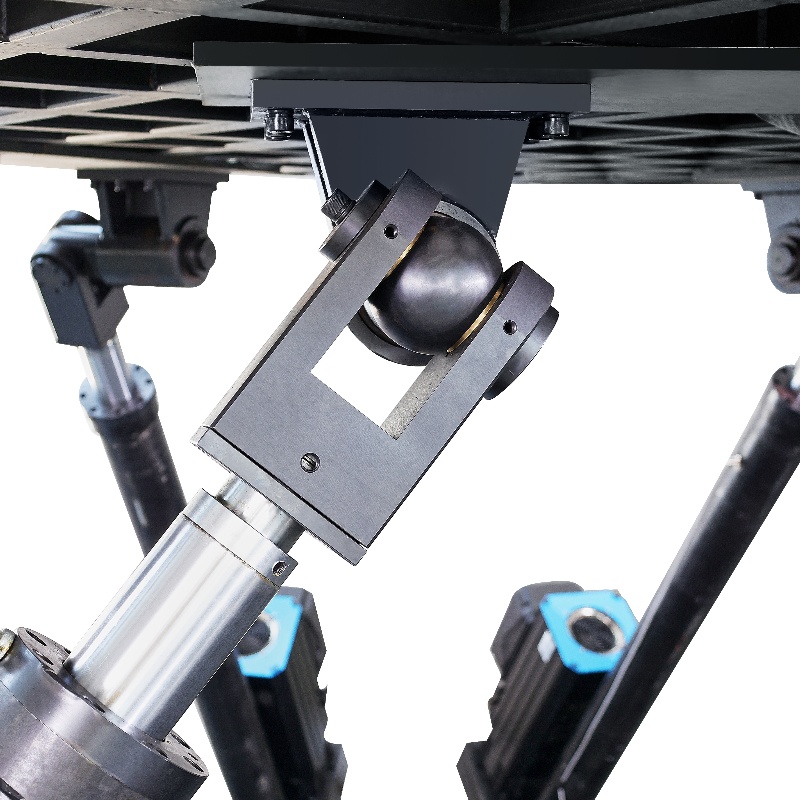

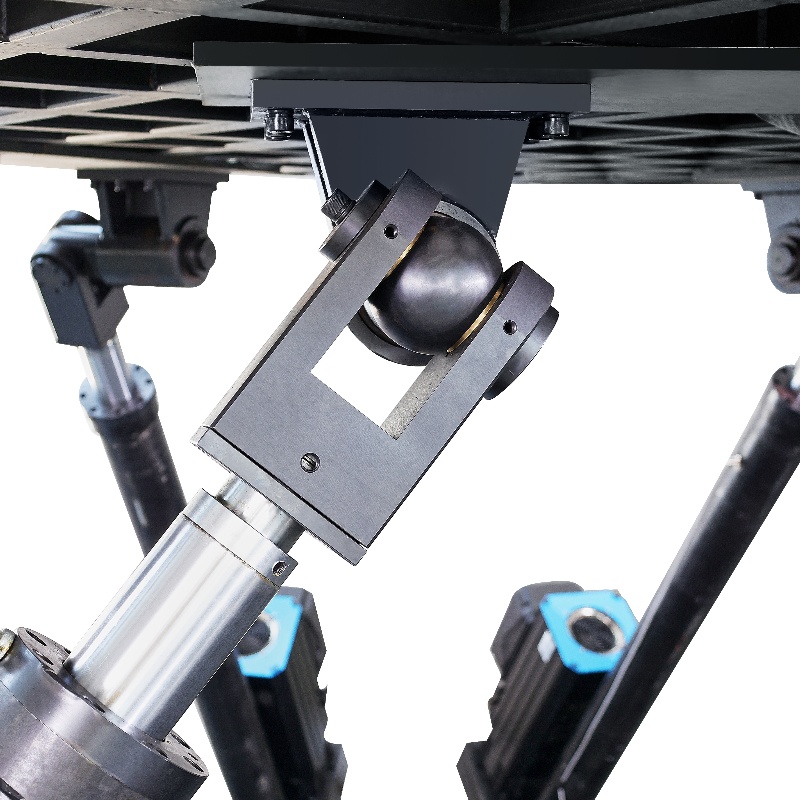

To address these challenges, engineers often use parallel kinematic designs, such as Stewart platforms, which distribute loads evenly across actuators. High-strength alloys and reinforced frames support the heavy payload without sacrificing responsiveness. Additionally, integrating high-resolution sensors provides real-time feedback, enabling dynamic adjustments to maintain motion fidelity. These solutions ensure the platform performs reliably even under demanding industrial testing conditions.

Benefits of High Payload Capacity

A 6DOF motion platform with a 18000 kg payload capacity offers significant advantages for heavy-duty industrial testing:

Versatility: It can accommodate large, heavy test specimens like automotive chassis, aerospace components, or industrial machinery.

Realism: Testing full-scale equipment under realistic motion conditions improves the accuracy of simulation results.

Efficiency: Eliminates the need for multiple smaller tests, saving time and resources.

Safety: Allows controlled, repeatable motion for heavy objects that would be risky to test otherwise.

Scalability: Supports future testing needs as payload requirements grow.

This capacity enables industries to push the boundaries of product development and quality assurance, ensuring components withstand real-world stresses.

Real-World Applications

Industries leveraging 6DOF platforms with such high payload capacities include:

Automotive Testing: Simulating road conditions and vehicle dynamics on full chassis to evaluate durability and performance.

Aerospace: Flight simulators and vibration testing of large aircraft parts or satellite components.

Heavy Machinery: Stress testing of construction equipment or industrial robots under dynamic loads.

Defense: Testing armored vehicles and weapon systems under realistic motion scenarios.

Energy Sector: Simulating conditions for turbines, generators, or offshore equipment.

For example, a 6 axis motion platform can replicate the complex vibrations and movements a heavy-duty vehicle experiences, enabling engineers to identify potential failure points early. This reduces costly recalls and enhances safety.

Tip: When selecting a 6DOF motion platform for heavy-duty testing, prioritize platforms with proven structural integrity and advanced control systems that ensure precise movement even at maximum payload capacity.

Key Features of the 6DOF Motion Platform

Precision and Stability

A 6DOF motion platform designed for heavy-duty industrial testing must deliver exceptional precision and stability. When handling a payload as massive as 18000 kg, even the slightest deviation or vibration can compromise test results. To ensure accuracy, these platforms employ rigid structural frameworks paired with finely tuned actuators that control motion across all six axes—surge, sway, heave, roll, pitch, and yaw.

Stability is achieved through advanced damping mechanisms and real-time feedback loops that counteract unwanted oscillations. This level of control is crucial for applications like automotive chassis testing or aerospace component simulations, where consistent, repeatable motion is vital. Unlike DIY 6 dof motion platform projects or smaller 6dof motion simulators diy, industrial-grade systems maintain smooth operation under heavy loads without sacrificing responsiveness.

Advanced Control Systems

At the heart of a high-capacity 6dof platform lies an advanced control system. These systems integrate sophisticated algorithms that manage actuator coordination, motion trajectory, and load balancing. They support programmable motion profiles, enabling users to simulate complex real-world scenarios with high fidelity.

Many platforms offer user-friendly interfaces, and some even provide API access compatible with popular programming environments like Python or MATLAB. This flexibility allows engineers to customize tests, automate procedures, and analyze data efficiently. While hobbyists might explore arduino 6dof motion platform projects for learning, industrial platforms prioritize robustness, precision, and integration with existing test infrastructure.

High-Resolution Sensors

To maintain exact positioning and motion accuracy, high-resolution sensors are embedded throughout the platform. These sensors continuously monitor position, velocity, acceleration, and force feedback across all six degrees of freedom. The data collected enables the control system to make real-time adjustments, ensuring the platform follows the intended motion path flawlessly.

Such sensor systems often include encoders, accelerometers, and gyroscopes with resolutions far exceeding those found in typical 6dof motion sim or diy 6dof flight simulator setups. This precision is essential to meet the stringent requirements of heavy-duty industrial testing, where even minor inaccuracies can lead to flawed product evaluations or safety risks.

Tip: When evaluating a 6dof platform for heavy industrial use, prioritize systems with integrated high-resolution sensors and advanced control algorithms to guarantee precise and stable motion under maximum payload conditions.

Comparing 6DOF Platforms for Heavy-Duty Testing

Performance Metrics

When evaluating a 6DOF motion platform for heavy-duty industrial testing, several performance metrics are crucial. Accuracy across all six degrees of freedom—surge, sway, heave, roll, pitch, and yaw—is essential to replicate real-world conditions precisely. The platform must maintain smooth, vibration-free motion even under maximum payload, such as 18000 kg. Responsiveness, or how quickly the platform reacts to control inputs, affects test fidelity and repeatability.

Load distribution is another key metric. Platforms using parallel kinematics, like Stewart platforms, evenly share loads among actuators, enhancing stability and durability. Additionally, the platform's stiffness and damping characteristics influence its ability to resist deformation and absorb shocks, which is vital when testing large automotive chassis or aerospace components.

For DIY enthusiasts exploring a 6 dof motion platform diy or arduino 6dof motion platform projects, these industrial-grade metrics might be aspirational but highlight the complexity involved in heavy-duty applications.

Cost vs. Capability Analysis

The price of a 6dof motion platform varies widely depending on payload capacity, precision, and control system sophistication. Industrial platforms with a 18000 kg payload command a premium due to the robust materials, high-torque actuators, and advanced sensors required. While the 6dof motion platform price for heavy-duty models can be substantial, the investment often pays off by enabling comprehensive testing in a single setup, reducing the need for multiple smaller tests.

In contrast, smaller 6dof platforms or 6dof motion simulator diy kits are more affordable but lack the load capacity and precision needed for heavy industrial testing. When selecting a platform, decision-makers should balance budget constraints against testing requirements. Sometimes, opting for a mid-range 6 axis motion platform with modular upgrade options offers a practical path forward.

Market Leaders and Innovations

Several companies lead the market in high-payload 6DOF motion platforms. Innovations focus on improving actuator efficiency, integrating AI-driven control algorithms, and enhancing sensor resolution. Some platforms now offer seamless software integration with popular engineering tools, enabling custom motion profiles and real-time data analysis.

Emerging designs also incorporate lighter yet stronger composite materials, reducing the platform's own weight and improving dynamic response. While hobbyists might experiment with diy 6dof flight simulator builds or 6 degrees of freedom flight simulator platforms, industrial leaders push the boundaries of scale and precision.

Notably, platforms like the MOTIONMASTER-6 Stewart Platform demonstrate how parallel kinematics and advanced servo actuators deliver precise motion for diverse heavy-duty applications. Such innovations underscore the importance of selecting a platform that aligns with specific industrial testing needs, ensuring reliability and repeatability.

Tip: When comparing 6dof platforms for heavy-duty testing, prioritize those offering proven load distribution, high-precision control systems, and scalable software integration to maximize test accuracy and operational efficiency.

Industrial Applications of 6DOF Motion Platforms

Automotive Testing

The automotive industry relies heavily on 6DOF motion platforms to simulate real-world driving conditions. A 6dof platform with a 18000 kg payload can support entire vehicle chassis, allowing engineers to test suspension, durability, and safety systems under dynamic motions. Unlike smaller 6dof motion simulator diy projects, these industrial platforms deliver precise and repeatable movements across all six degrees of freedom—surge, sway, heave, roll, pitch, and yaw. This enables realistic simulation of road vibrations, cornering forces, and braking impacts. The result? Better vehicle designs that meet safety standards and customer expectations.

Aerospace Simulations

In aerospace, 6 axis motion platforms are essential for replicating flight conditions. Full-scale components like aircraft wings or satellite modules can be mounted on heavy-duty 6dof platforms to undergo vibration and stress testing. This ensures structural integrity during turbulence, takeoff, and landing scenarios. Flight simulators with 6 degrees of freedom flight simulator platforms provide pilots with immersive training experiences, replicating real cockpit motions. While hobbyists may explore diy 6dof flight simulator builds, industrial-grade platforms offer the payload capacity and precision required for aerospace certification testing.

Large-Scale VR/AR Experiences

Large-scale virtual reality (VR) and augmented reality (AR) setups benefit from 6DOF motion platforms to enhance immersion. Platforms capable of handling heavy payloads can support bulky VR rigs, motion seats, or simulator cockpits. This allows users to experience realistic motion cues synchronized with visual content. While 6dof motion simulator diy kits offer entry-level experiences, professional VR installations demand robust 6dof platforms with advanced control systems and high-resolution sensors to avoid motion sickness and ensure smooth operation.

Tip: When deploying 6DOF motion platforms in industrial applications, match the platform’s payload and precision capabilities to the specific testing or simulation requirements to maximize performance and reliability.

Challenges and Solutions in Heavy-Duty Testing

Common Obstacles

Heavy-duty industrial testing with a 6DOF motion platform, especially one handling payloads up to 18000 kg, faces several common challenges. First, managing the sheer weight without compromising precision is critical. Heavy payloads can cause structural deformation, actuator strain, and control instability. Additionally, vibration and resonance issues may arise, risking damage to both the platform and the test specimen. Another obstacle is ensuring repeatability of complex multi-axis motions under such loads, which is essential for reliable data. Environmental factors like temperature fluctuations can also affect sensor accuracy and actuator performance. For those interested in building a 6 dof motion platform diy or a diy 6dof flight simulator, these challenges highlight why industrial-grade platforms differ significantly from hobbyist projects.

Technological Advancements

To overcome these obstacles, recent technological advancements have been integrated into modern 6dof platforms. High-strength materials, such as reinforced alloys and composite structures, provide the necessary rigidity without excessive weight. Actuators now feature improved torque-to-size ratios, enabling smooth, powerful motion control even under heavy loads. Advanced control algorithms use real-time feedback from high-resolution sensors to dynamically adjust actuator movements, compensating for inertia and external disturbances. Integration with software platforms allows precise programming of motion profiles and automated error correction. Furthermore, innovations in sensor technology, including ultra-precise encoders and inertial measurement units, enhance positioning accuracy. These advancements ensure that even a 6 axis motion platform with a 18000 kg payload can operate with the precision needed for heavy-duty industrial testing.

Case Studies of Successful Implementations

Several industries demonstrate successful application of heavy-duty 6DOF motion platforms. For instance, automotive manufacturers use large 6dof platforms to test full vehicle chassis under simulated road conditions, identifying weaknesses before production. Aerospace companies employ similar platforms for vibration and fatigue testing of large aircraft components, ensuring compliance with stringent safety standards. In one notable case, a defense contractor utilized a 6dof motion sim to replicate battlefield vehicle dynamics, enabling safer and more effective equipment design. Another example includes energy sector firms testing turbine assemblies on heavy-duty platforms to simulate operational stresses. These real-world implementations prove that addressing the challenges with the right technology leads to reliable, repeatable testing outcomes.

Tip: When selecting a 6DOF motion platform for heavy-duty industrial testing, focus on platforms that combine robust structural design with cutting-edge control systems and sensor integration to overcome common challenges and ensure precise, stable operation under maximum payload conditions.

Future Trends in 6DOF Motion Platforms

Emerging Technologies

The future of 6DOF motion platforms is shaped by several emerging technologies that promise to enhance performance and expand applications. One key advancement is the integration of AI-powered control systems. These systems can learn from real-time data, optimizing actuator response and improving motion accuracy even under heavy payloads like 18000 kg. This reduces the need for manual tuning and increases repeatability.

Another trend involves the use of lightweight composite materials. These materials reduce the platform’s own weight while maintaining structural strength, allowing faster and more energy-efficient motion. This is particularly beneficial for heavy-duty industrial testing, where minimizing inertia improves responsiveness.

Sensor technology is also evolving. Next-generation high-resolution encoders, inertial measurement units (IMUs), and force sensors provide ultra-precise feedback. Combined with edge computing, these sensors enable real-time adjustments that keep the platform stable and accurate during complex multi-axis motions.

Potential for Innovation

Innovation in 6dof platforms extends to modular designs and customizable configurations. Manufacturers are developing platforms that can be tailored to specific industry needs, such as interchangeable actuator modules or scalable payload capacities. This flexibility allows companies to start with a smaller 6dof platform and upgrade as testing demands grow, balancing 6dof motion platform price considerations.

Additionally, software advancements are enabling more intuitive user interfaces and seamless integration with simulation environments. Engineers can program complex motion profiles or connect platforms to VR setups for immersive testing. This opens doors to new applications beyond traditional industrial testing, including advanced flight simulators and large-scale VR experiences.

Moreover, the DIY community continues to influence innovation. While industrial 6 axis motion platforms focus on heavy-duty performance, hobbyists experimenting with arduino 6dof motion platform or diy 6dof flight simulator projects often drive creative ideas that can inspire commercial solutions.

Impact on Industry Standards

As these technologies mature, we can expect updates to industry standards governing 6DOF motion platforms. Enhanced precision and control capabilities will raise the bar for performance benchmarks, ensuring platforms meet stricter safety and reliability criteria. Standards may also evolve to include interoperability protocols, allowing different platforms and software to communicate seamlessly.

For sectors like aerospace and automotive, where certification is critical, these advancements will streamline testing processes and improve data quality. Regulatory bodies might adopt new testing guidelines that leverage the capabilities of high-payload 6dof platforms, fostering innovation while maintaining safety.

Tip: Stay ahead by choosing 6DOF motion platforms that incorporate AI-driven controls, modular designs, and advanced sensors to ensure compliance with evolving industry standards and future-proof your heavy-duty testing capabilities.

Conclusion

Handling a 18000 kg payload on a 6DOF motion platform poses engineering challenges, but solutions like high-strength alloys and advanced control systems ensure precision and stability. Such platforms benefit industries by enabling realistic simulations, enhancing safety, and supporting scalability. As technology advances, the integration of AI and modular designs will further improve performance and industry standards. FDR provides innovative 6DOF motion platforms that offer unparalleled precision and reliability, making them ideal for heavy-duty industrial testing.

FAQ

Q: What is a 6DOF Motion Platform with a 18000 kg payload used for?

A: A 6DOF Motion Platform with a 18000 kg payload is ideal for heavy-duty industrial testing, accommodating large, heavy specimens like automotive chassis and aerospace components, ensuring precise and realistic simulations.

Q: How does a 6DOF Motion Platform maintain precision with heavy loads?

A: The platform uses high-strength materials, advanced control systems, and high-resolution sensors to maintain precision and stability, even with a 18000 kg payload.

Q: What factors affect the 6DOF Motion Platform price?

A: The price depends on payload capacity, precision, control system sophistication, and material quality, with higher costs for platforms supporting heavier loads like 18000 kg.

Q: Can I build a DIY 6DOF Motion Platform for industrial use?

A: While DIY projects like a diy 6dof flight simulator are possible, industrial-grade platforms require advanced engineering to handle heavy payloads and ensure precision.